1200c Rotary Tube Furnace Automatic Loading and Unloading with Float Fowmeter

Description

Basic Info.

| Model NO. | STGX-60-12PRO |

| Power | 6kw |

| Voltage | AC 380V Single Phase, 50/60 Hz |

| Maximum Temperature | 1600c |

| Tube Material | Al2O3 Tube |

| Tube Size | Dia 80mmx1000mmlength |

| Transport Package | in Plywood Case |

| Specification | CE/ISO9001 certificate |

| Trademark | Sante |

| Origin | China |

| HS Code | 8514 |

| Production Capacity | 50sets/Month |

Product Description

Products purposeThe automatic feeding and discharging rotary tube furnace is composed of a heating system, an automatic rotary mechanism, an automatic feeding and discharging kit and a furnace body tilting mechanism. The furnace tube can rotate 360° and the speed can be adjusted; Output selection and online adjustment of feeding speed, the furnace body can be tilted by 15°, and the end of the furnace tube is equipped with a material collection device, which can realize continuous small-batch production such as product research and development or product pilot test. This product is mainly used in inorganic non-metallic compounds Special equipment for particle powder sintering heat treatment in materials, lithium battery positive and negative electrode materials, ceramic materials, new energy and new materials industries.Main features:

1. The shell is made of metal Q235 low-carbon steel, and the surface is electrostatically resistant and resistant to corrosion.

2. The solid double-layer metal frame is combined with the heat-insulating fan structure, and the furnace surface temperature is low

3. Horizontal use mode, upper opening structure, easy to operate

Refractory material

Multi-layer insulation design, composed of lightweight alumina ceramic fiber and high-quality insulation board backing, does not contain asbestos components, low heat loss and low energy consumption.

Heating system

1. High-quality HRE spiral resistance wire heating element is safely and firmly embedded on the surface of the furnace, and is heated by free heat radiation in the furnace cavity, which is energy-saving and efficient, and has a long service life

2. Ring heating by resistance wire to achieve good uniformity in the furnace

Temperature control panel

1. Advanced controllers that meet complex process requirements

2. Programmable 30 program segments to realize automatic curve temperature control

3. Over temperature and fault alarm, automatic safety protection

Rotary and automatic feeding system

1. The furnace tube adopts a gear transmission electric drive structure to rotate 360°, 12-20rpm adjustable, and the material is heated evenly in the furnace tube

2. The furnace body can be tilted by electric drive, the tilt angle can be adjusted, and the material can enter and exit more smoothly.

3. Equipped with an automatic screw feeding device, the feeding speed is adjustable, and there is material collection at the end to realize continuous material processing

Specifications:

| Item | STGX-60-12PRO | STGX-100-12PRO | STGX-150-12PRO | STGX-200-12PRO |

| Tube Size | Φ60×1200mm | Φ100×1200mm | Φ150×1500mm | Φ200×1800mm |

| Heating Zone | 440mm | 440mm | 600mm | 800mm |

| Max Temperature | 1200ºC | |||

| Work Tempearture | 1100ºC | |||

| Heating Element | HRE high temperature alloy resistance wire | |||

| Chamber Material | Polycrystalline inorganic alumina ceramic fiber material prepared by wet vacuum filtration | |||

| Temperature accuracy | ±1ºC | |||

| Thermocouple | N type thermocouple | |||

| Temperature Controller | Intelligent microcomputer PID temperature control instrument, SSR voltage regulation control, PID parameter self-tuning function; programmable 32 program segments, program temperature rise, program heat preservation, program cooling | |||

| Heating Rate | 1-20ºC/min freely adjustment | |||

| Furnace Strcuture | Furnace temperature control integrated structure | |||

| Protection | Modular control, sound and light alarm signal will be sent out for over temperature and broken coupler in the working process, and the protection action will be completed automatically | |||

| Safety Protection | The equipment is equipped with a circuit breaker, which will automatically pop open in case of short circuit leakage, which can protect the safety of equipment and operators | |||

| Furnace Shell | High-quality cold-rolled steel plate CNC machine tool blanking processing, after welding, grinding, polishing, phosphating, pickling, surface electrostatic spraying plastic powder | |||

| Cerfiticate | ISO9001 CE SGS TUV | |||

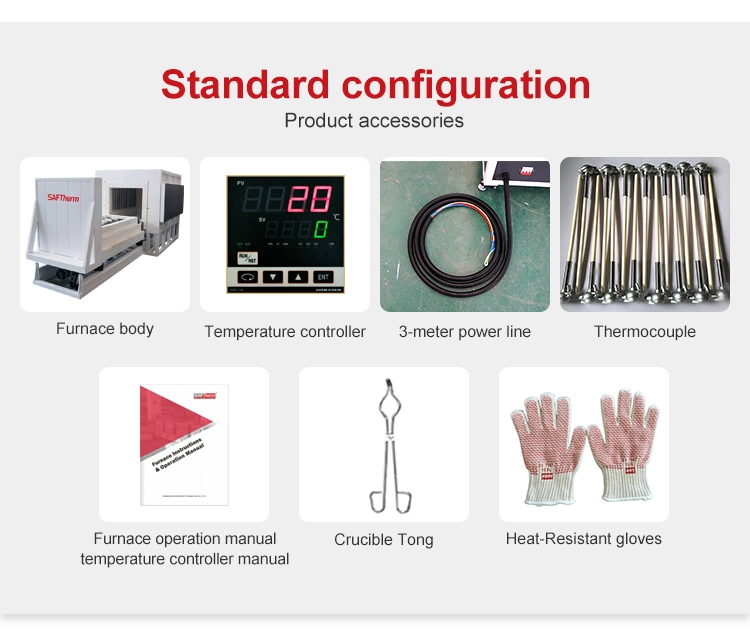

| Standard Accessories |

| |||

| OEM | According to the output requirements of the actual material of the user, the customization of special specifications of the product can be realized | |||

Packaging & Shipping

1) Packing: from the inside to outer packaging, is foam sponge, carton, wooden case.

2) Transport modes: Sea or Air transportation, TNT, DHL express or FedEx.

3) Please make sure the 'shipping address' is your confirmed address.

4) We do check everything in good condition before we ship your parcel out.

5) We will process your order ASAP after payment is confirmed

Company Information

Henan Sante Furnace Technology Co., Ltd. is a high-tech enterprise located in Luoyang area of Henan, China Free Trade Zone. Sante is one of the leading electric heat furnace manufacturers in China. The company designs, manufacturers and sells kinds of electric resistance furnaces and provides the professional solutions for customers in lab and heat industry. Sante has delivered its furnaces to more than 78 countries and the team is fully dedicated to working for their beloved career.

SANTE products cover 1000ºC~1800ºC Muffle furnace, Tube furnace, Vacuum furnace, Dental furnace, Industrial furnace, elevator furnace, car bottom furnace, degreasing furnace, heardening furnace, annealing furnace, pusher furnace, shutterpottery kiln and so on

Our goal is to continuously meet the various demands for various kinds of high temperature heating treatment muffle furnace and to be the world first-class enterprise with providing excellent service and high-quality products for our cooperation partners!

FAQ

1: Are you a factory?

Yes. We are China leading laboratory and industrial heating treatment furnace manufacturer, which integrates design, manufacture and sales for nearly 20 years.

2: Do you have customization or OEM service?

We can customize furnaces as product, work piece size, and temperature requirement. Meanwhile, we offer OEM service under the strict industrial standard.

3: What is the lead time?

Normally within 15 working days after receiving the advanced payment or depends on order quantity.

4: How can you guarantee the production quality?

Firstly, we are ISO9001:2008 and CE certified factory, all the processes are strictly following the standard of the metallurgy process; secondly. We have QC department who perform strictly in each producing process including package.

5: How long is your furnace warranty period?

One year (expect thermocouple and heating element), lifetime support

6: What payment terms does SAFTHERM support?

T/T, L/C and so on.

Contact us:

Marketing Manager: Caleb Li

Add: No.4, Sunxin Road, Luoyang Free Trade Zone, Henan, China

Prev: Rotary Dynamic Sintering with High

Next: Cheap Price Regenerative Aluminium Melting Furnace for Billet Casting

Our Contact