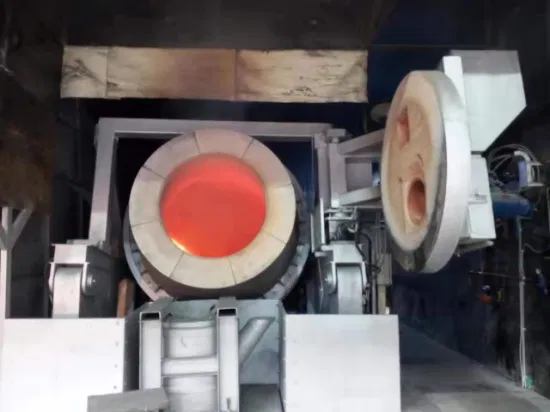

5t Natural Gas/Oil Rotary Furnace

Guangzhou Longxin Regenerative Industrial Furnace Co., Ltd., founded in 2010, is a national high-tech enterprise, specia

Description

Basic Info.

| Model NO. | : LX-HZL01-10 |

| Hydraulic Unit Power | 7.5kw |

| Total Power | 15-25kw |

| Demand for Flue Gas Treatment Capacity | 30000 M ³/ H |

| Appearance Size | 3300 * 4710 * 3260mm |

| Flue Gas Temperature at Furnace Mouth | Below 220 Degrees |

| Power of Automatic Refueling Device | 2.2kw |

| Swing Speed | 1.5-3 Rpm |

| Processing Speed | Hot Aluminum Ash 2-4 Hours/Furnace Times |

| Treatment Capacity | Hot Aluminum Ash Treatment 5 Tons/Furnace Times |

| Swing Angle | 360 Degrees |

| Recovery | Rate ≥ 80% |

| Feeding Mode | Forklift and Semicircular Ash Hopper |

| Drive Mode | Guide Rail Friction Drive |

| Specification | 5t |

| Trademark | LXXR |

| Origin | Guangzhou, China |

| HS Code | 8417100000 |

| Production Capacity | 100sets/Year |

Product Description

Guangzhou Longxin Regenerative Industrial Furnace Co., Ltd., founded in 2010, is a national high-tech enterprise, specializing in the R&D, design, production, manufacturing, installation, maintenance and technical transformation of renewable aluminum melting and casting processing equipment.Its main products include aluminum melting furnace and holding furnace, regenerative combustion system, rotary kiln, aluminum chip mechanical pump, vacuum aluminum water transfer device, aluminum liquid degassing equipment, ingot line, casting rod equipment, online monitoring system, etc.Aluminum Melting Furnace features:

1,Model: fixed furnace, double chamber furnace, side pool aluminum scrap furnace, tilting furnace, rotary furnace2,Specification: 1.5 tons to 100 tons3,Melting speed: 3~12t/h4,Fuel: natural gas, liquefied gas, heavy oil, diesel, tire oil;5,Raw materials: aluminum ingot, aluminum scrap, scrap aluminum, pop can6,Equipped with burners: regenerative, top mounted, top mounted, integral and bottom mounted;

The rotary furnace is used for aluminum slag treatment. It can handle cold slag, hot slag and aluminum slag with high iron content. It can not only reduce the manual operation of frying ash, but also ensure higher metal aluminum recovery.Equipment performance:Treatment capacity: hot aluminum ash treatment 5 tons/furnace times (cold aluminum slag treatment about 3.5t)Swing speed:1.5-3 rpmProcessing speed: hot aluminum ash 2-4 hours/furnace times (cold aluminum slag 3-5 hours)Recovery: rate ≥ 80% (depending on the technical level of operators)Swing angle: 360 degreesDrive mode: Guide rail friction driveFeeding mode: Forklift and semicircular ash hopperDischarging mode: hydraulic inclined discharging, and discharging by forklift and semicircular ash hopperTotal power: 15-25KWDrive motor power: 11KWHydraulic unit power :7.5KWPower of automatic refueling device :2.2KWCombustion gun power: 4KW (optional)Flue gas temperature at furnace mouth: ≤ 220 ºCDemand for flue gas treatment capacity: 30000 m ³/ hAppearance size: 3300 * 4710 * 3260mm

Our Contact

Send now