Acme Rotary Furnace, High Temperature Rotary Calcination Furnace, Rotary Reduction Furnace

Description

Basic Info.

| Model NO. | RF-400-4(G) |

| Tube Material | SUS304/SUS310S/Ra330/Ra600 |

| Sealing Type | Fill Sealing/Graphite+Metal Sealing |

| Heater Material | 0cr21al6nb, 0cr27al7mo2 |

| Refractory Material | Silicate Aluminum Fiber |

| PLC | Omron/Siemens |

| Temperature Controller | Shimaden/Eurotherm |

| Operation Panel | Simulation Screen/Touch Screen/Industrial Computer |

| Loading Type | Vacuum Feeding |

| Temperature Uniformity (°c) | ±5 |

| Max.Temperature (°c) | 1050 |

| Process Gas of Rotary Reduction Furnaces | Ar/N2/H2/Nh3 |

| Heating Method | Electric/ Natural Gas |

| Heating Zone | 4 |

| Heating Chamber Length (mm) | 5600 |

| Tube Diameter (mm) | 400 |

| Transport Package | Wooden Box |

| Specification | 12000 × 4000 × 4000 |

| Trademark | ACME |

| Origin | China |

| HS Code | 8514199000 |

| Production Capacity | 50 |

Product Description

Product Description

Pusher type furnace is mainly suitable for metal powder (like tungsten, moly, etc) reduction and powder metallurgy part sintering

Application

Product specification

| SpecModel | RF-400-4(G) | RF-600-5(G) | RF-800-6(G) |

| Tube diameter (mm) | 400 | 600 | 800 |

| Heating zone | 4 | 5 | 6 |

| Heating chamber length (mm) | 5600 | 6500 | 8000 |

| Max.temperature (°C) | 1050 | 1050 | 1050 |

| Temperature Uniformity (°C) | ±5 | ±5 | ±5 |

| Heating method | Electric/ natural gas | ||

| Process gas of rotary reduction furnaces | Ar/N2/H2/NH3 | ||

| Total size L×W×H (mm) | 12000 × 4000 × 4000 | 14000 × 5000 × 4500 | 16500 × 5500 × 4500 |

| The above specifications are defined according to tungsten powder reduction process. These specifications can be adjusted to the process requirements, they are not as acceptance standard, the detail spec. will be stated in the technical proposal and agreements. | |||

Technical Features

1. The rotary reduction furnaces use rotary tube which will result in good powder fluidity.

2. The intermittent loading and unloading type assures good sealing performance and low gas consumption with gas recycling.

3. Full automatic loading and unloading is available, which assures stable product quality and low labor force.

4. Furnace has the functions of remote control operation, remote malfunction diagnosis and remote program update functions.

Optional Configuration

1. Refractory material: silicate aluminum fiber/alumina ceramic fiber/high alumina brick

2. Heater material: 0Cr21Al6Nb, 0Cr27Al7Mo2

3. Tube material: SUS304/SUS310S/RA330/RA600

4. Sealing type: fill sealing/graphite+metal sealing

5. Loading type: vacuum feeding/vibration feeding/manual feeding

6. Operation panel: simulation screen/touch screen/industrial computer

7. PLC: OMRON/Siemens

8. Temperature controller: SHIMADEN/EUROTHERM

9. Thermocouple: C type/S type/N type

10. Recorder: Paperless recorder/paper recorder, Foreign brand/Chinese brand

11. Electric components: CHINT/Siemens

Project process

discussion on technical questions--prepare technical proposal and commercial quotation--confirm technical proposal--sign contract--Advance payment(T/T)--layout drawing discussion and confirmation--production--installation and commissioning--quality inspection--Pre-acceptance--second payment(T/T)--disassembling and packaging--dispatch and shippment--installation , commissioning and training at Buy's plant--final acceptance-- final payment(T/T)--after-sales service

WHAT CAN WE DO FOR YOU?

Basic Functions: A R&D Center For New Equipment A;Pilotscale Experiment Platform For Customer A; Teaching Practice And Training Base.ACME Provides Custom Furnace Design Service, Though We Have Standard Specifications. Our Custom Furnace Systems Can Reach Extremely High Heating Temperature, And Create High-Quality Finished Products. Our Highly Experienced Engineers Can Design The Furnace In The Way You Want - As Big As You Need.The Furnace Can Operate At Your Desired Temperature, And Produce The Large Quantity And High Quality Products. Whether You Are More Concerned With Costs Or Capabilities, Our Custimized Furnace Will Meet Those Needs. Our Furnaces Are Designed To Do Our Best To Meet Your Application, Budget And Schedule Requirements.All The Products Sold Out Can Enjoy One Year Warranty. All ACME Customers Have Access To Aftermarket Replacement Parts, Spare Parts, Repair And Maintenance Services To Keep Their Furnaces Up And Running. ACME Owns Maintenance Records And Part Lists For Every Furnace We Have Ever Built, So Just A Phone Call Or An Email, You Will Get The Help From Us.

FAQ

Q1: Are you a factory?A1: Yes, we are a large factory that integrates research and development design, manufacturing and sales.Q2: Do you have technical support for the treatment technology and equipment ?A2: Yes. we could provide the customer with mature technical support.

Q3: What is the advantage about your company?A3: We have large factory, have special technical teams, who know the technology, process and equipment, have test center with many equipments which can treat customers' products before contract, best and fsat after-sales service, have much experience, have high credit and good economic basement.

Q4: Why should I choose your products?A4: Our products are high quality and reasonable priceQ5: Any other good service your company can provide?A5: Yes,we can provide good after-sale and fast delivery

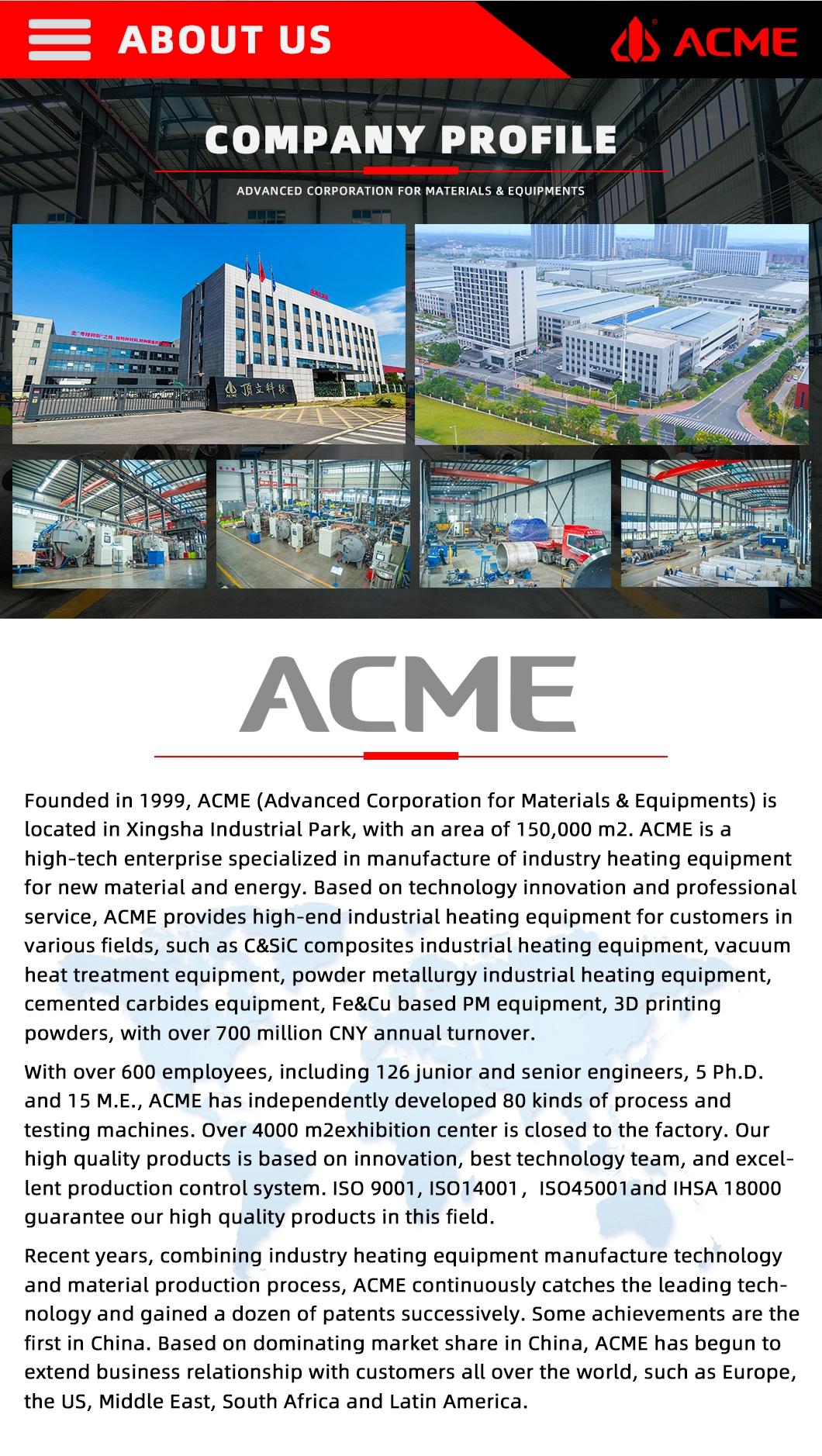

Company Profile

Prev: Vacuum Sintering Furnace to Produce Sic Products

Next: Acme Vacuum Brazing Furnace, Cab Furnace, Controlled Atmosphere Brazing Furnace

Our Contact