Industrial Electric High Temperature Induction Heat Treatment Atmosphere Vacuum Diffusion Welding Furnace Price

Application Mainly used for diffusion welding of metal materials, ceramic materials, etc. Structural features The heat s

Description

Basic Info.

| Furnace Temperature Uniformity | ±5ºC |

| Furnace Liner | Metal Liner or Graphite Liner |

| Convection Fan | Optional |

| Air Cooling Pressure | 2 PA |

| Max Temperature | 750 Degrees |

| Temperature Control Accuracy | ±1ºC |

| Heating Power | 24kw |

| Furnace Capacity | 100kg |

| Transport Package | International Standard |

| Trademark | SHLZK |

| Origin | Guangdong |

| HS Code | 8514191000 |

| Production Capacity | 100 |

Product Description

ApplicationMainly used for diffusion welding of metal materials, ceramic materials, etc.

Structural features

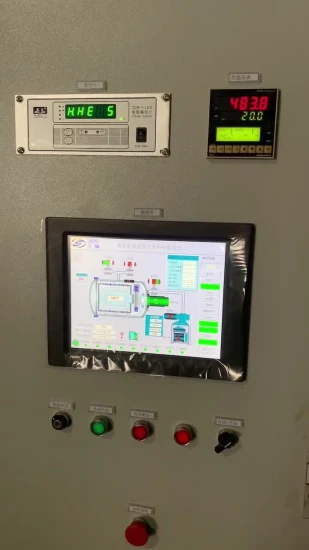

The heat shield has an all-metal radiation shield structure composed of two layers of molybdenum and four layers of stainless steel. The heating element is a wide molybdenum belt, which is evenly arranged along the front, rear, left and right walls to ensure the uniform furnace temperature. The pressure device is composed of a hydraulic station, an oil cylinder, a pressure head, a load cell, a pressure controller and a pressure support, which can realize oil pressure maintaining and pressure setting control. The electronic control system adopts PLC and programmable temperature controller to realize three control modes: automatic, semi-automatic and manual, and the operation is flexible.

Technical parameter

| 1. Maximum temperature | 1300ºC |

| 2. Temperature control accuracy | ±1C |

| 3. Furnace temperature uniformity | ±5ºC |

| 4. Ultimate vacuum | 6.7×103Pa |

| 5. Pressure rise rate | 0.5Pa/h |

Diameters

| 1. Indenter stroke - 80mm-150mm |

| 2. Indenter diameter - 60mm-200mm |

| 3. Controllable pressure - 0.02 ton-100 ton |

Company introduction

APS Induction Technology (Taizhou) Co., Ltd. is a rare high-tech enterprise in China with international leading technology in induction melting and heating field. At present, the capacity of induction melting furnaces produced can up to 70 tons, and the power supply can reach to 50,000kw. The heating equipment can be used in carbon-based/ceramic-based composite materials, carbon fiber/silicon carbide fiber, high-performance ceramics, graphite, vacuum diffusion welding, vacuum hot pressing, vacuum melting, powder metallurgy, environmental protection and other industrial.In addition, we are also a professional manufacturer of power control boards, induction coils, water-cooled cables, yokes, and reactors. Compared with other manufacturers in China, we have outstanding advantages in product price, quality control, and delivery time.As an industrial equipment manufacturer with R & D capabilities, we keep seeking a balance between product economy and practicability in continuous innovation to ensure that we can provide the most valuable production solutions for each application, reduce costs for our users and help them improve production competitiveness.We hope to establish a more efficient, clean, low-carbon and circular green casting system by supplying stable, high-efficiency, energy-saving, safe and relatively cheap induction melting and heating equipment, and contribute to global energy conservation and emission reduction.

Our Contact

Send now