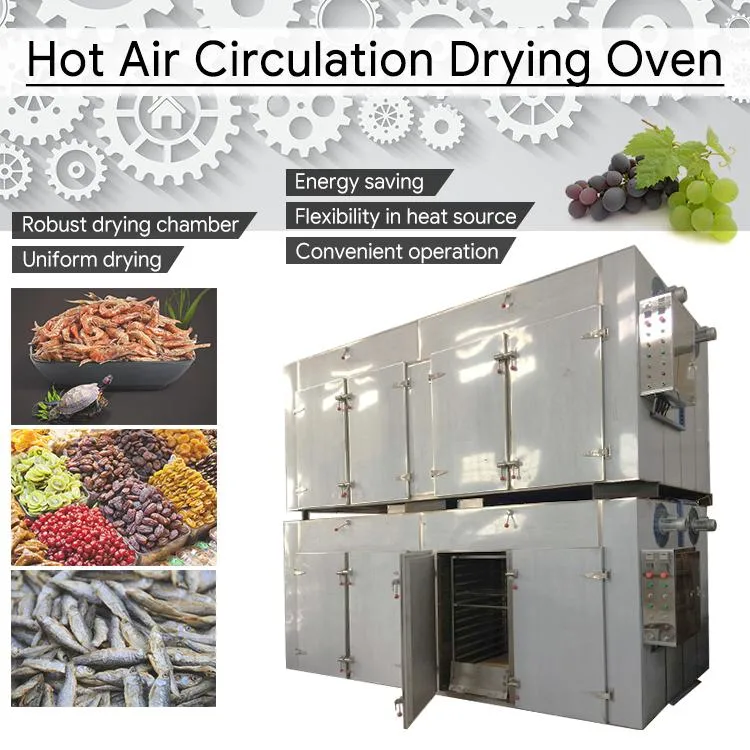

Fish Fruit Vegetable Dryer Processing Equipment Strawberry and Mango Hot Air Circulating Drying Oven

Description

Basic Info.

| Capacity | 50-400kg/H |

| Lead Time | 20 Working Days |

| Materials | Stainless Steel |

| Trays | 24-196 Tray |

| Operation Pressure | Atmospheric Pressure |

| Heating Method | Electric or Steam or Gas |

| Application | Fruit Vegetable Ect |

| Transport Package | Wooden Case |

| Trademark | GRT |

| Origin | China |

| Production Capacity | 20PCS/Month |

Product Description

Company Profile

·Zhengzhou Great Machinery Equipment Co., Ltd. established in 2005, located in Zhengzhou City, Henan Province, covering area about 300,00 square meters, with more than 100 employees which including R&D staffs more than 30 people.·The company is a set design,manufacture, installation, service in a body comprehensive enterprise, the core technology and the leading products for thevarious types of drying equipment, mixing equipment,granulating equipment, crushing equipment,screening equipment, and auxiliary equipment, productsare widely used in food, biology,medicine,chemical industry, and many other fields.·Companies adhere to science and technology as the backing,unceasingly absorbs the domestic and foreign advanced mechanical processing and designexperience, bold innovation, the introduction of high-quality talent,the strengthened enterprise internal management, actively participate in marketcompetition in a flexible management mechanism, strives for the survival by the quality, seek development by science and technology,with advancedmanufacturing technology,excellent equipment quality,first-class after-sales service, won the support and trust from the masses of customers at home andabroad.·Company has the rich production experience in the field of drying and talent, technology,management advantages, the company brings together industryhas a high-quality professional and technical staff, to provide users with complete sets of engineering design and manufacture, installation, debugging andtechnical operation training.Your satisfaction is our biggest wish,we uphold the idea, continuous efforts to improve their strength, the hardware and software for the general new andold customers with more quality products and services.

Product Description

| Model | Capacity(KG) | Powder(KW) | Steam To Be Consumed(M3/h) | Trays | Dimension LxWxH(MM) | Baking Cars |

| GRT-C-24 | 50 | 0.45 | 3400 | 24 | 1400X1200X2000 | 1 |

| GRT-C-48 | 100 | 0.9 | 3400 | 48 | 2300X1200X2000 | 2 |

| GRT-C-96 | 200 | 0.9 | 6800 | 96 | 2300X2200X2000 | 4 |

| GRT-C-144 | 300 | 1.35 | 10200 | 144 | 3200X2200X2000 | 6 |

| GRT-C-196 | 400 | 1.8 | 113600 | 196 | 4300X2200X2000 | 8 |

1. High safety, good insulation.The insulation layer is filled with high-density aluminum silicate cotton, and the high-density aluminum silicate cotton ensures the insulation of the oven and ensures the safety of the user.2.Multiple heating sourcesHeating heat source: steam, electricity, far infrared, electric steam.3. Two control system availableManual control system and computer control system are available4. Customized solutionsingle-door bicycles (24 pallets), two-door two-cars (48 pallets),two-door four-cars (96 pallets), three-door three-cars (72 pallets),three-door six-cars (144 pallets), four-door eight-cars. (192 trays)

Detailed Photos

Prev: Being Hot Air Circulating Drying Oven

Next: Powder Coat Curing Oven with Overhead Conveyor Track for Paint Drying Powder Coating

Our Contact