Powder Coat Curing Oven with Overhead Conveyor Track for Paint Drying Powder Coating

Gas Manual Powder Coating Curing Oven for Spray paint baking drying machine Manual Powder Coating Oven used for curing t

Description

Basic Info.

| Model NO. | JH-651822Q |

| Transport Package | Carton |

| Specification | 6500 x 1800 x2200mm |

| Trademark | JINHAI |

| Origin | China |

| HS Code | 8424899990 |

Product Description

Gas Manual Powder Coating Curing Oven for Spray paint baking drying machine

Gas Powder Coating Batch Oven is widely used in powder coating industry, the most reason people choose it is energy-saving comparing with electric oven, especially for large dimension, Gas Powder Coating Batch Oven will save more expense of energy consumption.

Techinal Parameters

| Model | JH-651822G |

| Inner Size (D x W x H ) | 6500 x 1800 x2200 mm |

| Heat source | Gas |

| Material | Galvanized steel sheet |

| Warm-up time | 15-30 min. (180° C) |

| Insulation material | A grade rock wool |

| Rock wool thickness | 100mm |

| Voltage | 110V/220V/380V, 2 phase or 3 phase |

2. Famous burner fully burns fuels, quickly reach to required temperature saving your production time everyday.

3. Circulation fans causes uniform temperature in the entire inner space that results in quality cured finishes.

4. 100 mm thickness rockwool board inserted between galvanized steel wall and durable steel skin always keeps the chamber a consistent high temperature with minimum heat loss.

5. Loading system can be customized to standard trolley system or track system applied to continous conveyor line.Details Images Gas Burner

Burner can be put in the side or top place

Famous gas burner takes full utilizations of fuels, reaching the baking temperature faster, making heating process more efficient and energy-saving. PLC ControllerThe PLC controller provides high-precision heating process, operators could set the desired temperature and heating timeaccurately on the panel.Once the curing time arrive, the oven will stop heating automatically. The control panel also includes safety devices: alarm lightand emergency stop buttons, etc.Oven Wall Materials100mm thick rockwool board density 120kgs/cbm, built with heat-resistent galvanized innerwall and durable color steel outwall to form a sandwich insulation structure. This is an optimum design to maintain the temperature in oven chamber.Circulation FanCirculation fan circles the hot air to warm the oven interior, minimize temperature difference and guarantee uniform-heated chamber. There is a isolation strip between fan and motor that tends to protect the motor from burning hot and extend its life.

Q1: Are you trading company or manufacturer ?

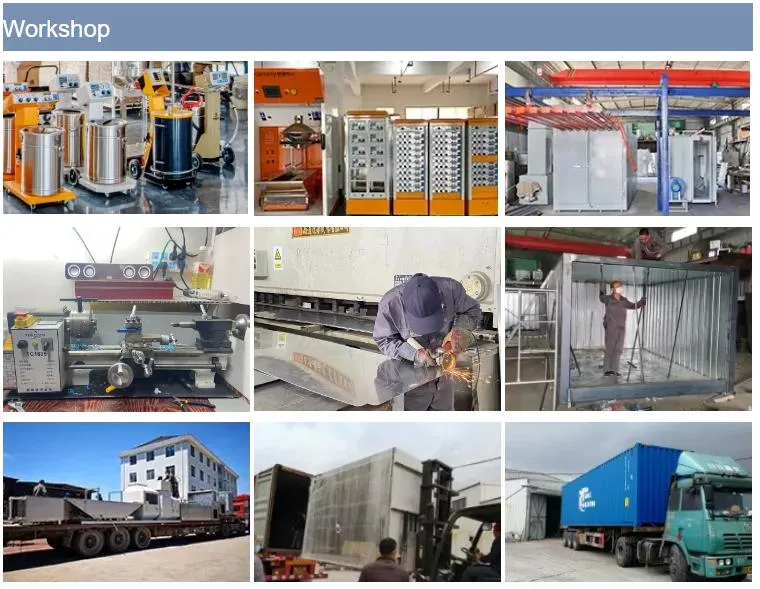

A: We are manufacturer which exported to many countries and we are specialized in producing powdercoating equipment more than 10 years in China.

Q2: What about the lead time ?

A: Generally it is 3-5 days if the goods are in stock. or it is 15-30 days if the goods are not in stock, it is according to product and quantity.Q3: Can I customized the machines?Yes, we are a professional team for powder coating equipments, Our technician will design for you specially according to your needs and your factory, workpiece etc information.

Q4: Can you do OEM?

A: Yes, the product size can do customized.Q5: How long is the warranty?

A: Our warranty is 12 months.

Q6: Can you install for us?Yes, we can install overseas for you. But the engineers overseas installation cost, round trip air tickets, accommodation, meals and transport charges are on the buyers.

Prev: Fish Fruit Vegetable Dryer Processing Equipment Strawberry and Mango Hot Air Circulating Drying Oven

Next: Fish Dryer Processing Equipment / Fish Drying Equipment

Our Contact

Send now